Environmental Responsibility

Quality That Respects The Environment

Environmental responsibility is a top priority at SR International. All manufacturing and quality processes conform to applicable environmental regulations and follow international environmental standards.

We operate an integrated waste management system comprising:

All liquid and solid wastes are disposed of in an environmentally safe and legally compliant manner, ensuring protection of both human welfare and the environment.

Our Commitment

- ✓ Strict in-house quality control

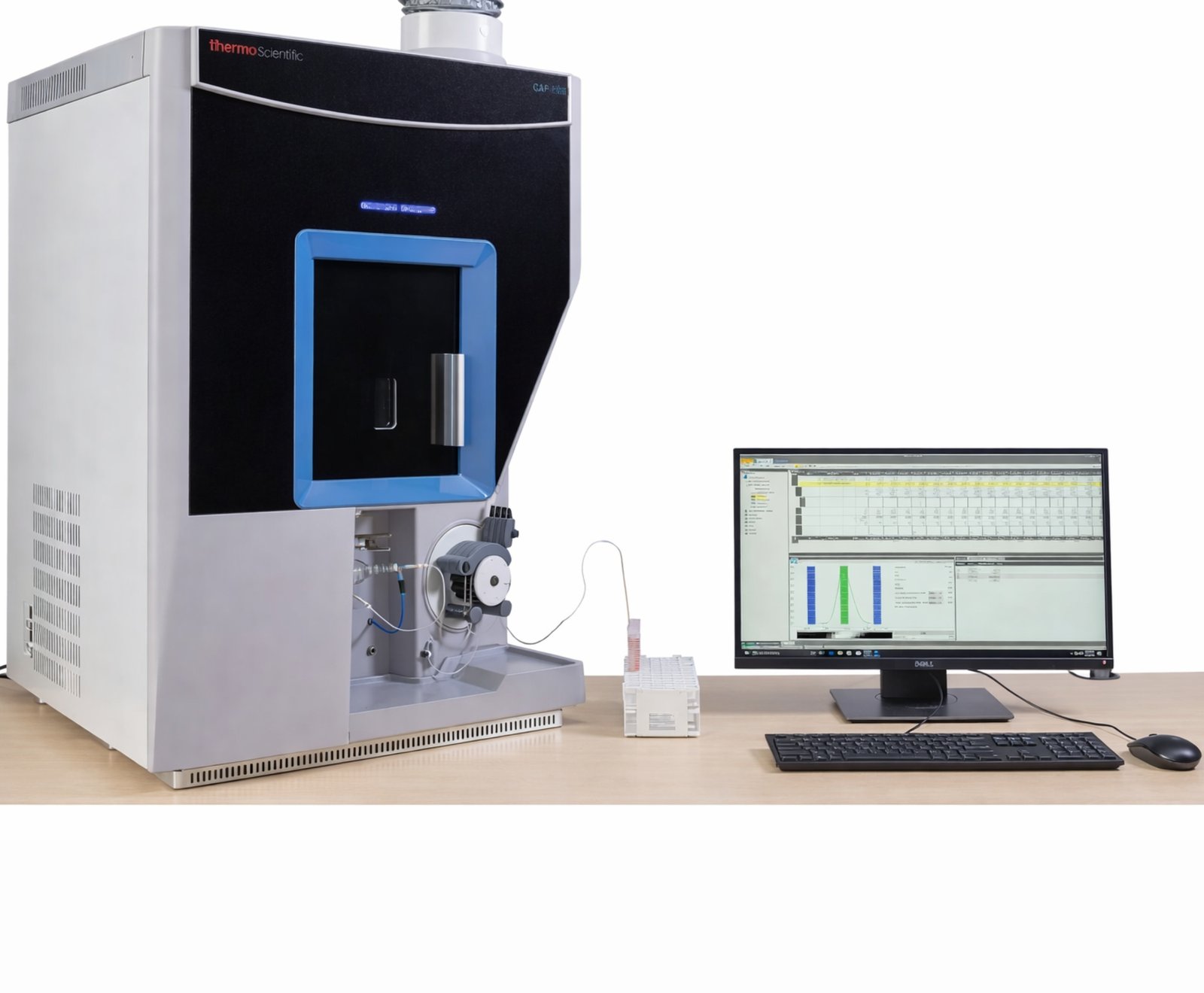

- ✓ Advanced analytical testing

- ✓ Responsible sourcing of raw materials

- ✓ Environmental compliance

- ✓ Continuous improvement